EDM Rings

2001

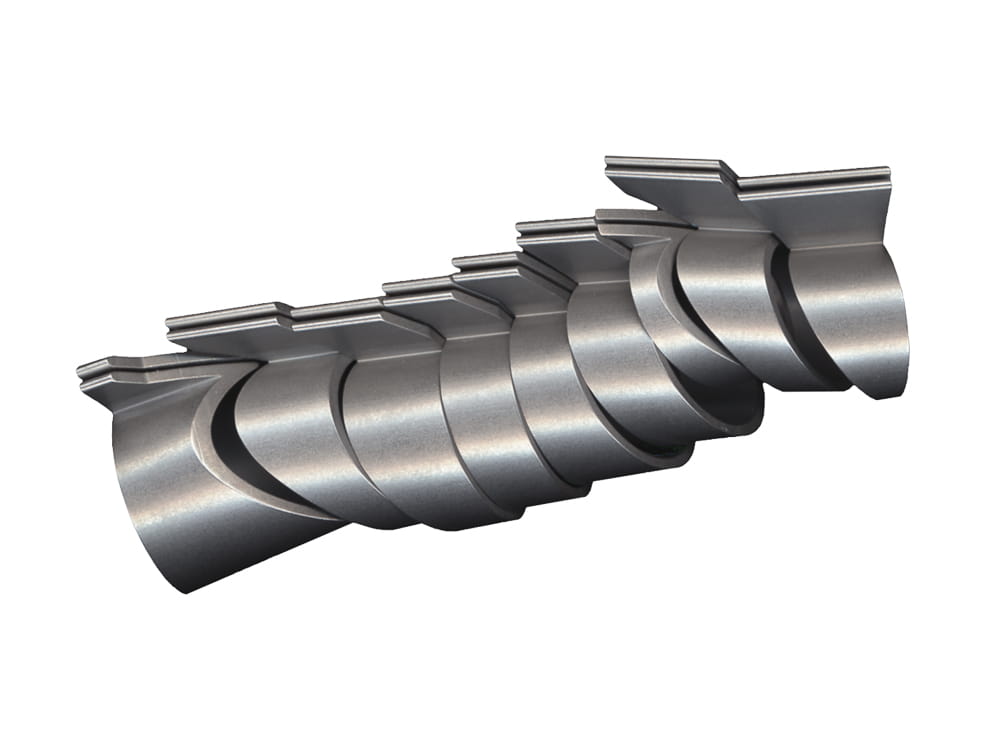

The concept behind the EDM* rings is to produce a series of rings varied in shapes and sizes through two acts – first, by carving a block metal into a conical shape, and second, by slicing the cone-shaped metal crosswise with a slight diagonal. The EDM Rings were intended to be produced in titanium but were prototyped in stainless steel, dramatically reducing its machining time due to the material’s higher conductivity.

*There are several types of Electrical Discharge Machining (EDM). The EDM Rings were machined using the Wire EDM process, which employs a thin, electrically charged wire to cut through metal and other conductive materials with high precision. This technique is especially effective for manufacturing complex shapes and intricate parts that would be challenging or impossible to achieve with traditional machining methods.