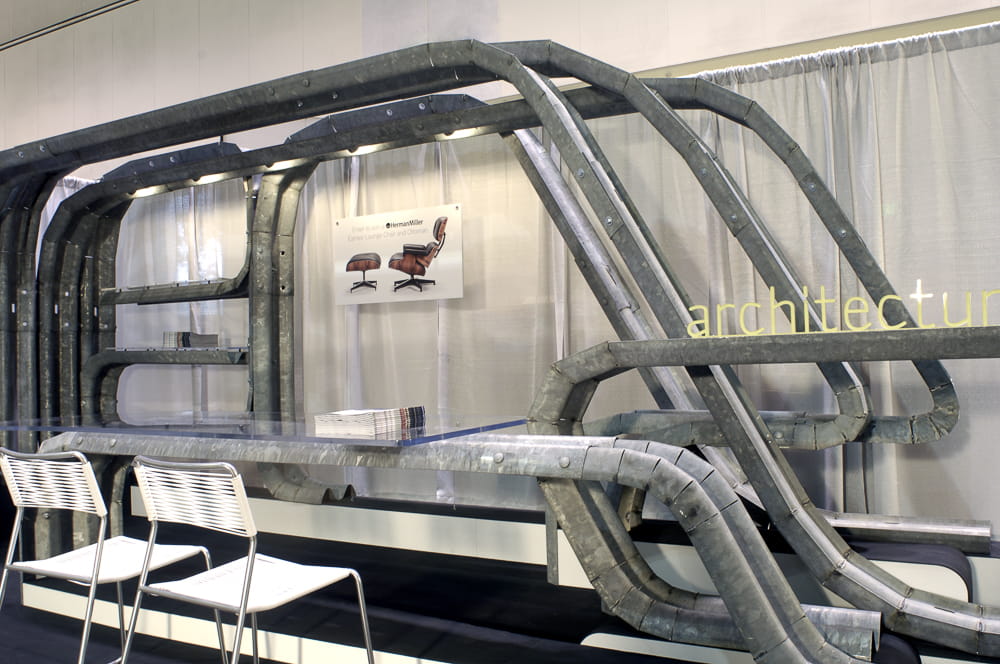

Architecture Magazine Booth

2006

Lookinglass Architecture & Design

Special thanks to Julie Eakin

The Architecture Magazine Booth was a convention booth commissioned by the magazine for the National AIA Convention 2006 held in Los Angeles. The convention coincided with the relaunch of the magazine, which underwent a significant visual and editorial redesign and featured a more modern and appealing layout. The content structure was updated to include more in-depth features, interviews, and case studies, and it was integrated with its digital version.

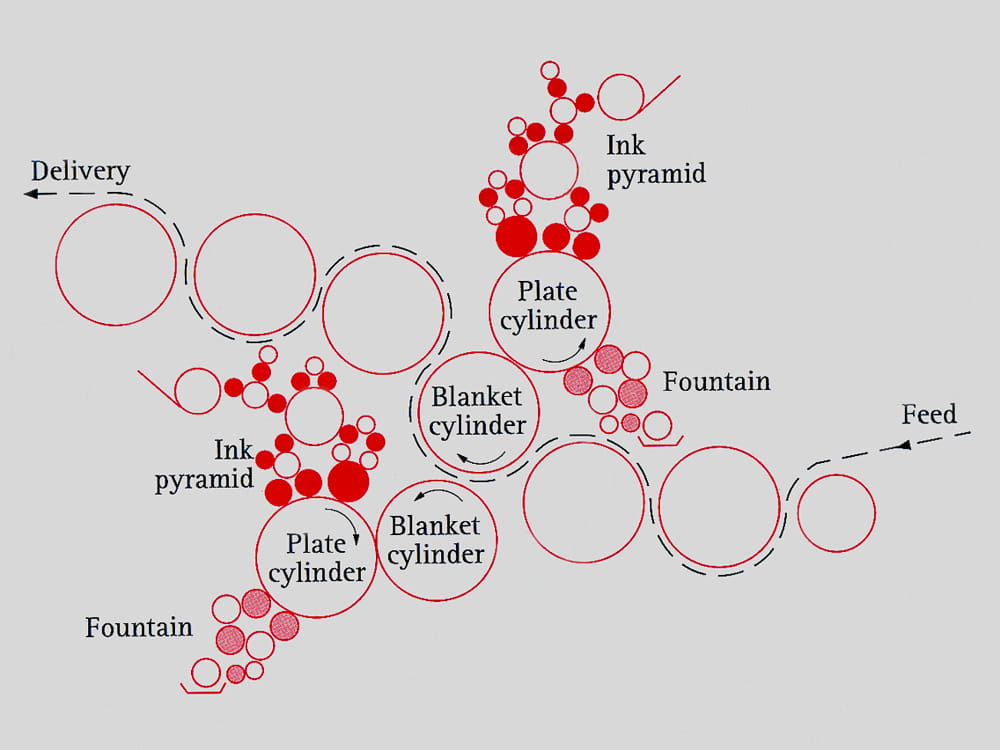

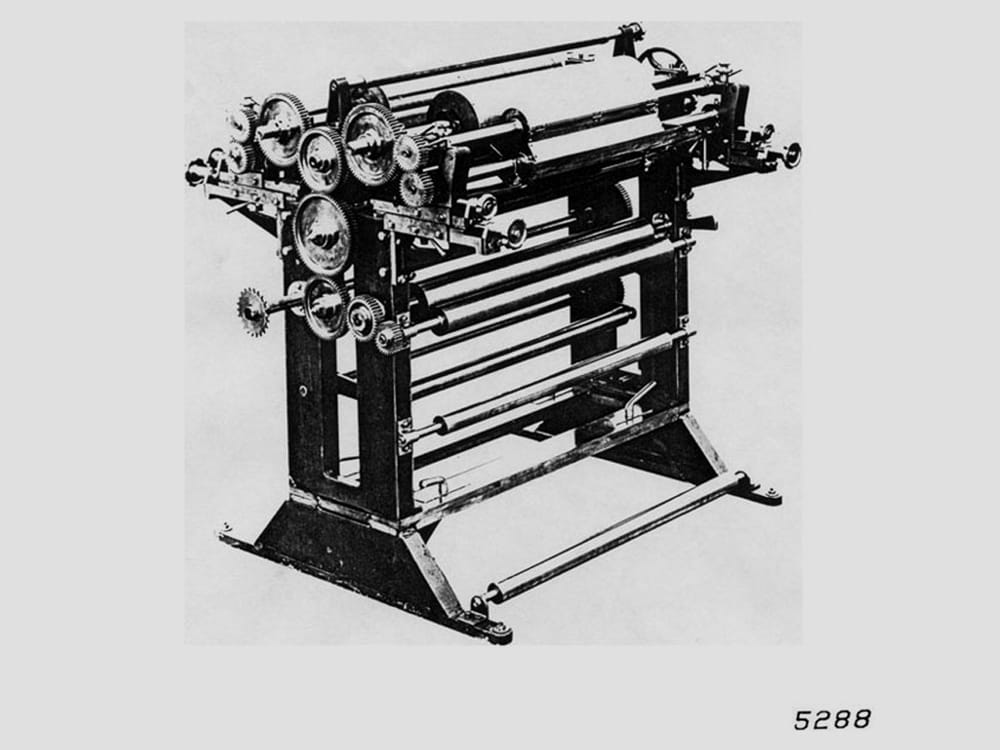

At the time of commission, the relaunched issue was titled “Reuse” but had not yet been printed by the press. Partnered with Lookinglass Architecture & Design (LGD), Yeh Design Lab provided a convention booth design to reinforce the relaunched issue’s focus by combining the ubiquitous freeway guardrails with the idea of paper paths through a printing press, signaling the convention’s location, the material’s reuse, and the magazine’s commitment to printed publications. The booth aimed to provide the required functional programs such as seating, shelving/storage, and counter surface necessary for the publication’s staff to interact with the convention attendees within the standard 10’x20’ booth footprint and be a striking “billboard” for advertising purposes.

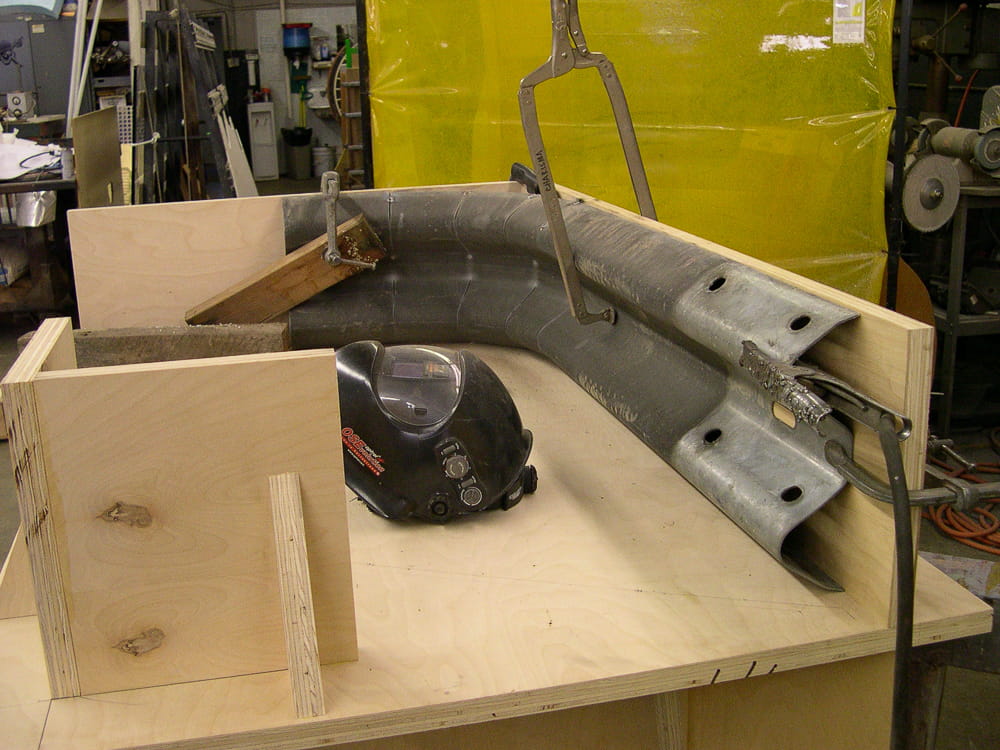

The California Department of Transportation (CalTrans) quickly granted the material donation while LGD refined and engineered the booth geometry, splicing, connections, and methods of material transformation. Freeway guardrails are designed to withstand impacts at various angles and speeds, redirecting vehicles and minimizing occupant injury. Guardrails undergo rigorous crash testing to ensure they meet safety standards and performance criteria; as such, the only way to deform the guardrail without forceful impact is to remove the parts of the material that give it strength. Wedges of materials were water-jet cut and removed, bent to the prescribed curvature, and welded. Due to limited budget and tight schedule, we performed the majority of fabrication in-house, from cutting, grinding, jig making, and welding to installation rehearsal. The project was delivered in ten weeks, from commission to installation.

Design & Fabrication Team:

Emil Mertzel, and Nick Gillock, and Yi-Hsiu Yeh

Dry-Run Installation Team:

Yi-Hsiu Yeh, Emil Mertzel, Nick Gillock, Rob Rombold, and Wendy Bone

Final Installation:

Emil Mertzel and Los Angeles Convention Center Unionized Labor Team